| SPECIFICATION | i300 |

|---|---|

| Cutting Capacity at 0° [mm] : | 300×300 |

| Cutting Capacity at 45° [mm] : | 275×300 |

| Cutting Capacity at 60° [mm] : | 175×300 |

| Cutting Capacity at -45° [mm] : | 275×300 |

| Hydraulic Motor Capacity [HP] : | 1 |

| Main Motor capacity [HP] : | 3 |

| Cutting Speed [mtr/min] : | 20-100 |

| Blade Size [mm] : | 4860x34x1.1 |

| Coolant Motor Capacity [HP] : | 0.16 |

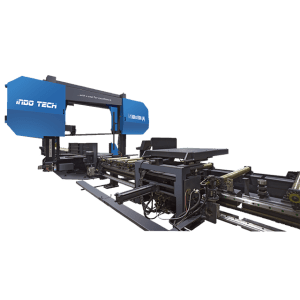

| Job Indexing : | Automatic/Manual |

| Indexing Stroke Available : | 500mm to 6000mm |

| Approx Weight [Kgs] : | 1600 |

| Overall Dimension [mm] : | 3000x1600x1900 |

| Coolant motor capacity [HP] : | 0.16 |

| Butt welder : | optional |

| Overall size [LxWxT in mm] : | 1800x1750x2300 |

| Approx weight [Kg] : | 1850 |

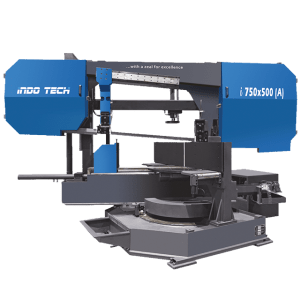

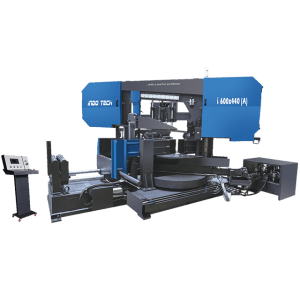

i 300 (A)

+ Free ShippingThe i 300 (A) Angular Precision Miter Cutting Machine, a cutting-edge double column bandsaw machine equipped with LM guides and a unique saw frame rotation for mitering flexibility.

- LM Guide Technology:** Ensures smooth and precise movement, enhancing the overall cutting accuracy and efficiency.

- Saw Frame Rotation for Mitering:** The machine offers the capability to rotate the saw frame, thanks to a large and accurate swivel type bearing. This feature allows for easy and precise positioning at various mitre angles.

- Motorized Cutting Arm Rotation:** Achieve the desired cutting angle effortlessly with the help of a geared motor, rotary encoder, and a high-end PLC & HMI control panel. This advanced technology ensures accurate and repeatable miter cuts.

- Heavy-Duty Horizontal Clamping:** The machine features robust horizontal clamping on both sides of the blade, providing secure and stable material fixation. The material remains fully bound during the entire cutting process, ensuring precise and reliable results.

- Roller Bearing Support:** Facilitating smooth rotation of the saw frame, the roller bearing support enhances operational stability, especially when dealing with heavy loads.

- Specially Designed Blade Guide Box:** The machine incorporates a meticulously designed blade guide box, optimizing blade alignment and ensuring efficient and consistent cutting performance.